Description

High-Density, FIFO Pallet Storage — Scalable & Simple to Use

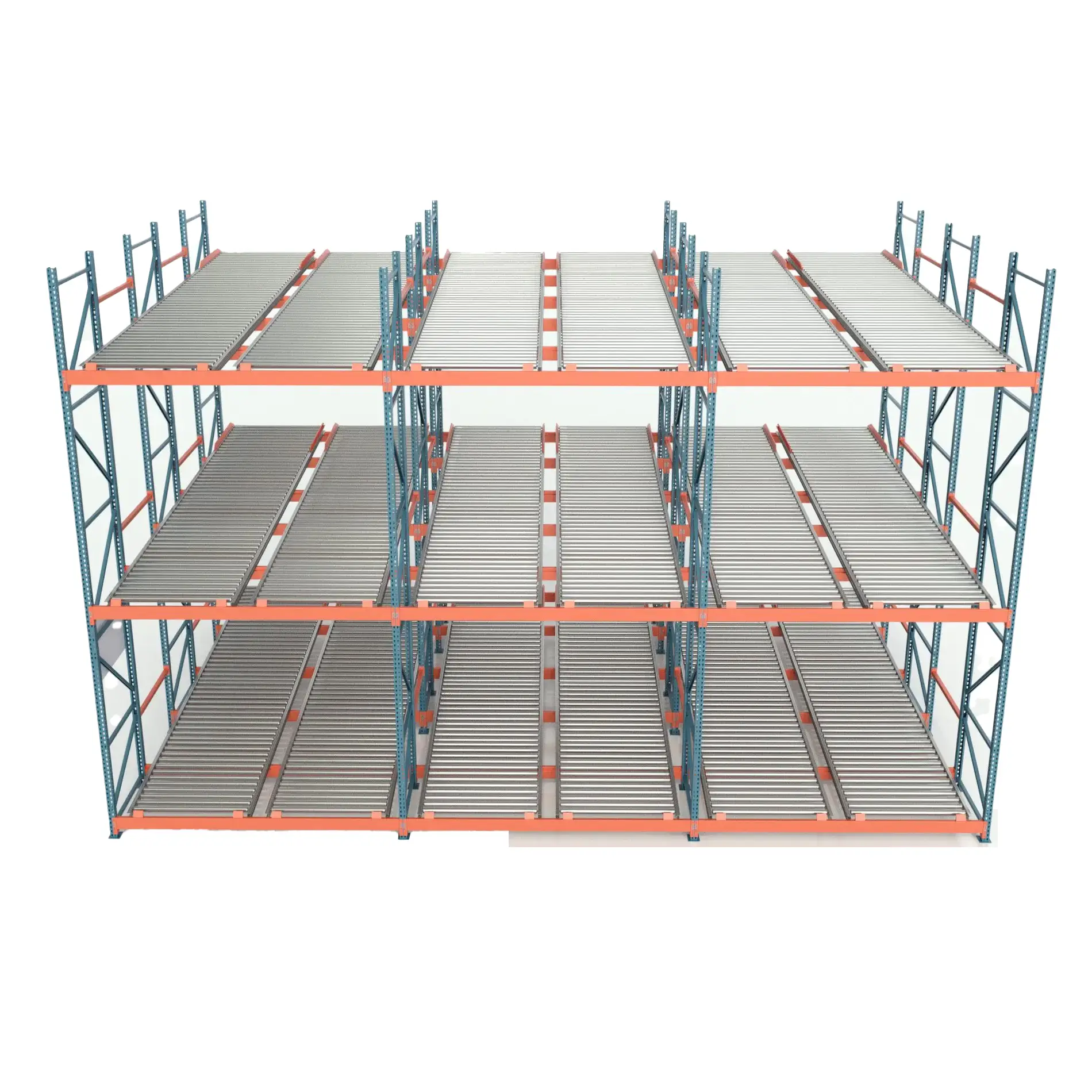

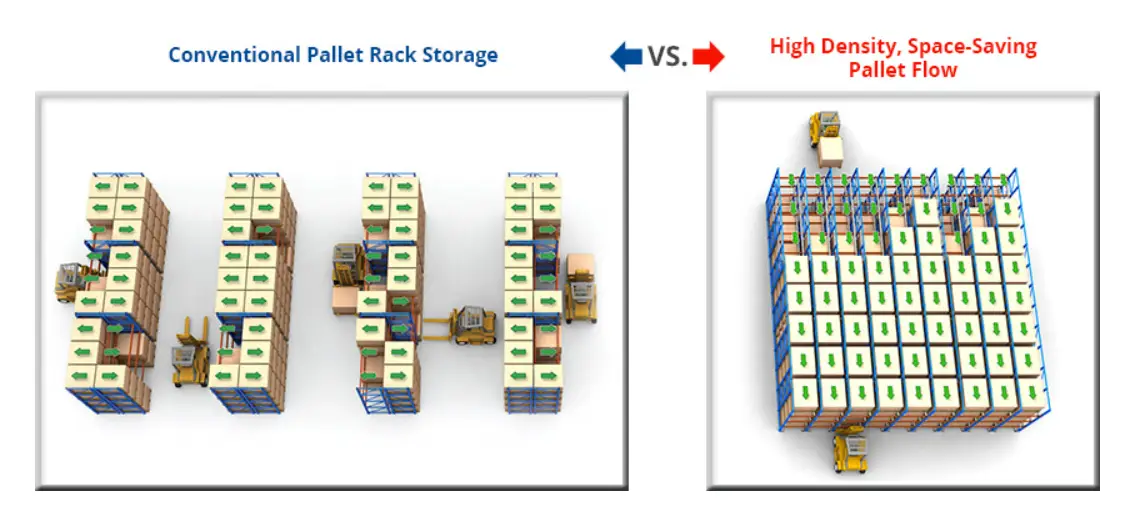

Do you have high-volume inventory for a moderate number of SKUs? Pallet flow rack maximizes your warehouse space by condensing pallet storage into deep, single-SKU lanes that harness the power of gravity to flow palletized inventory from one side of the system to the opposite side.

Pallet flow rack delivers greater pallet accessibility than other high-density systems and more flexibility in its cost-effective design –Do you need 3- to 4-pallets deep, or 9- to 10-pallets deep, or 20+ pallets deep? Pallet flow rack is completely scalable to your inventory and processing needs.

Pallet Flow Advantages:

- Scalable for 2-pallets to 20+ per SKU lane

- Affordable – low per-pallet cost vs. other HD storage

- Customizable – standard or non-standard pallets

- Configurable – FIFO or LIFO inventory rotation

- Trackable – dedicated SKU lanes

- Automatic – pick face auto replenished, no waiting

Pallet Flow Rack Delivers Powerful Results

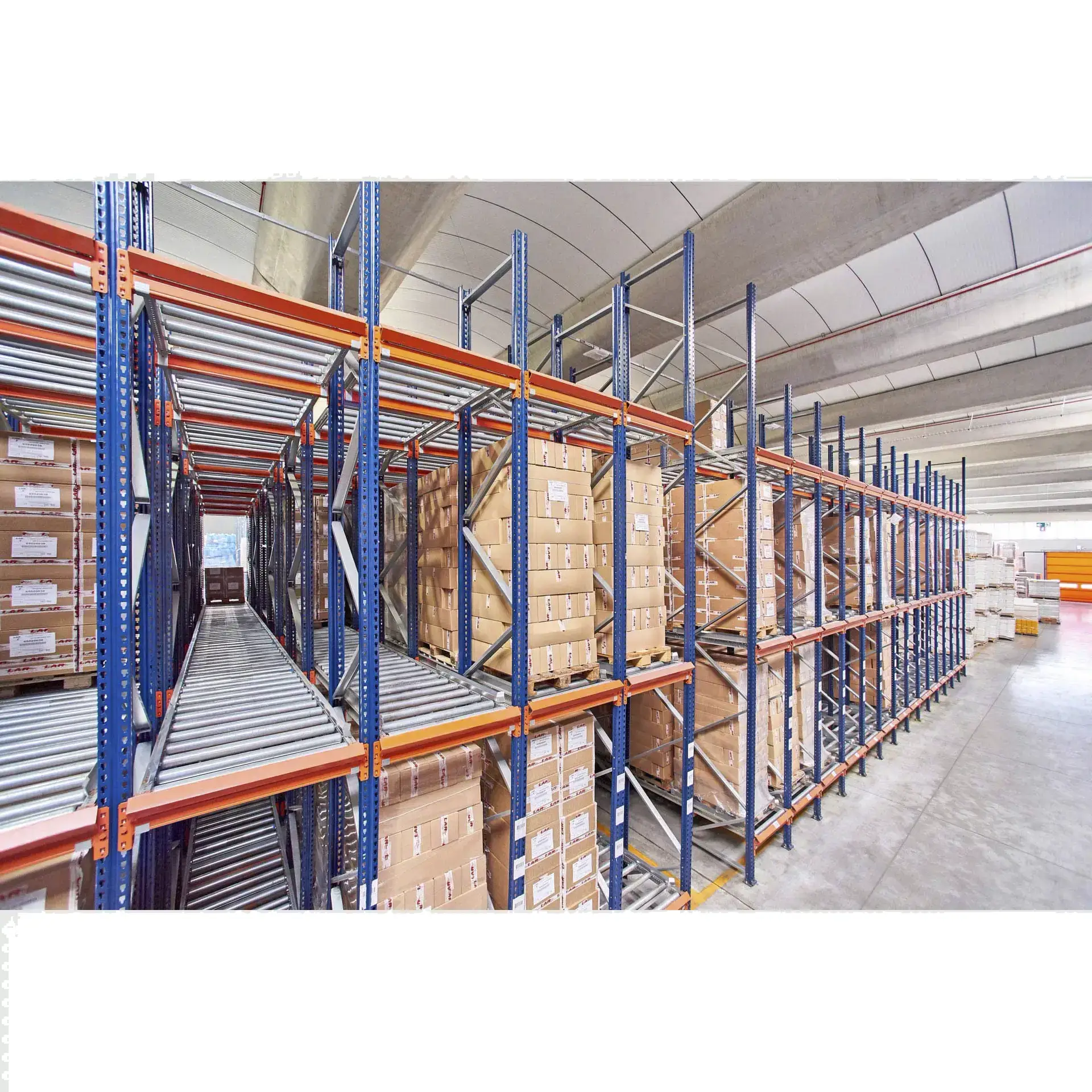

Pallet flow rack has broad application to solve warehousing, manufacturing, and distribution center challenges. We will design the solution you need, from condensed, multi-level systems to deep-lane case picking and push-assisted staging. If you can roll it, we can build it.

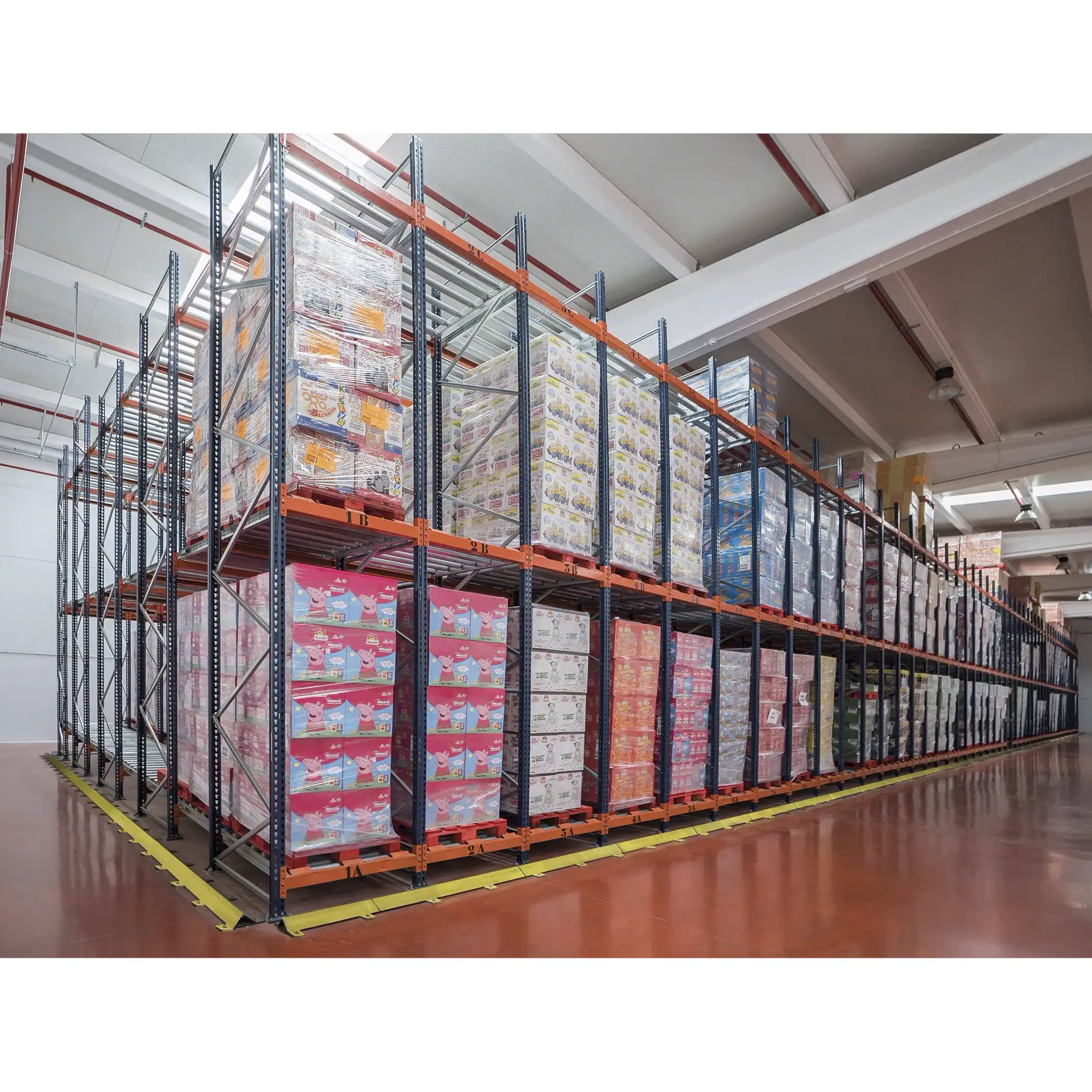

- Maximize Storage Capacity: Close to double the storage in the same footprint

- Increase Throughput: Less travel with consolidated picking and replenishment

- Decrease Equipment Costs: Few forklifts needed

- Reduce Labor Expense: Less forklift travel and pallet handling

- Better Inventory Control: Ideal for dated and/or perishable goods

Pallet Flow Racking FAQ

Pallet flow racking — also known as pallet live storage, gravity racking, and FIFO racking system — is the most agile high-density pallet storage system on the market. It comprises racks containing sloped rails with rollers upon which the loads slide. Its structure leverages gravity to streamline loading and unloading operations. In addition, the absence of interior work aisles increases the utilization of the available storage space.

Pallet flow racks have multiple benefits. First of all, they are the most agile high-density storage system with the best operational performance, making them an ideal solution for different types of warehouses. Likewise, their implementation ensures excellent inventory control. Moreover, the separation of the loading and unloading aisles eliminates interference, and the existence of a single SKU per storage channel facilitates product location and reduces extraction times. The pallet flow rack also guarantees maximum use of the available surface area, although the installation of deep channels could entail a certain loss of capacity in height (a slope of approximately 4% is required for the system to function correctly).

The main difference between these two types of racking systems is related to the inventory management method associated with each one. The pallet flow rack has two working aisles (one for loading and the other for unloading) and operates according to the FIFO (first in, first out) principle. Thus, the first pallet deposited in a channel is also the first to be removed. Push-back pallet racking, on the other hand, works in line with the LIFO (last in, first out) method. With only one working aisle, the last pallet stored in a channel is the first to be retrieved. In warehouses that manage perishable goods (e.g., food or pharmaceuticals), the pallet flow rack is the ideal alternative, as it prioritizes the removal of products with the closest expiry dates.